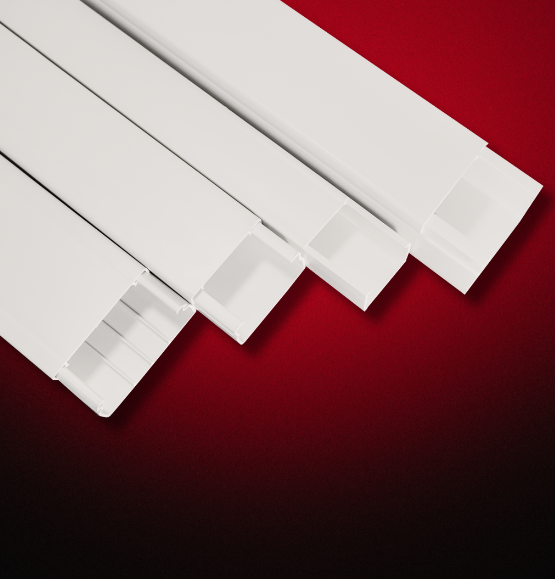

PVC Trunking

Organized Wiring Support

PVC Trunking offers a durable and efficient solution for managing and protecting electrical and telecom cables. Made from high-impact strength rigid PVC, it is available in various sizes and cross-sections, with excellent fire resistance, electrical insulation, and mechanical properties. Ideal for organized and safe cable routing in residential, commercial, and industrial settings.

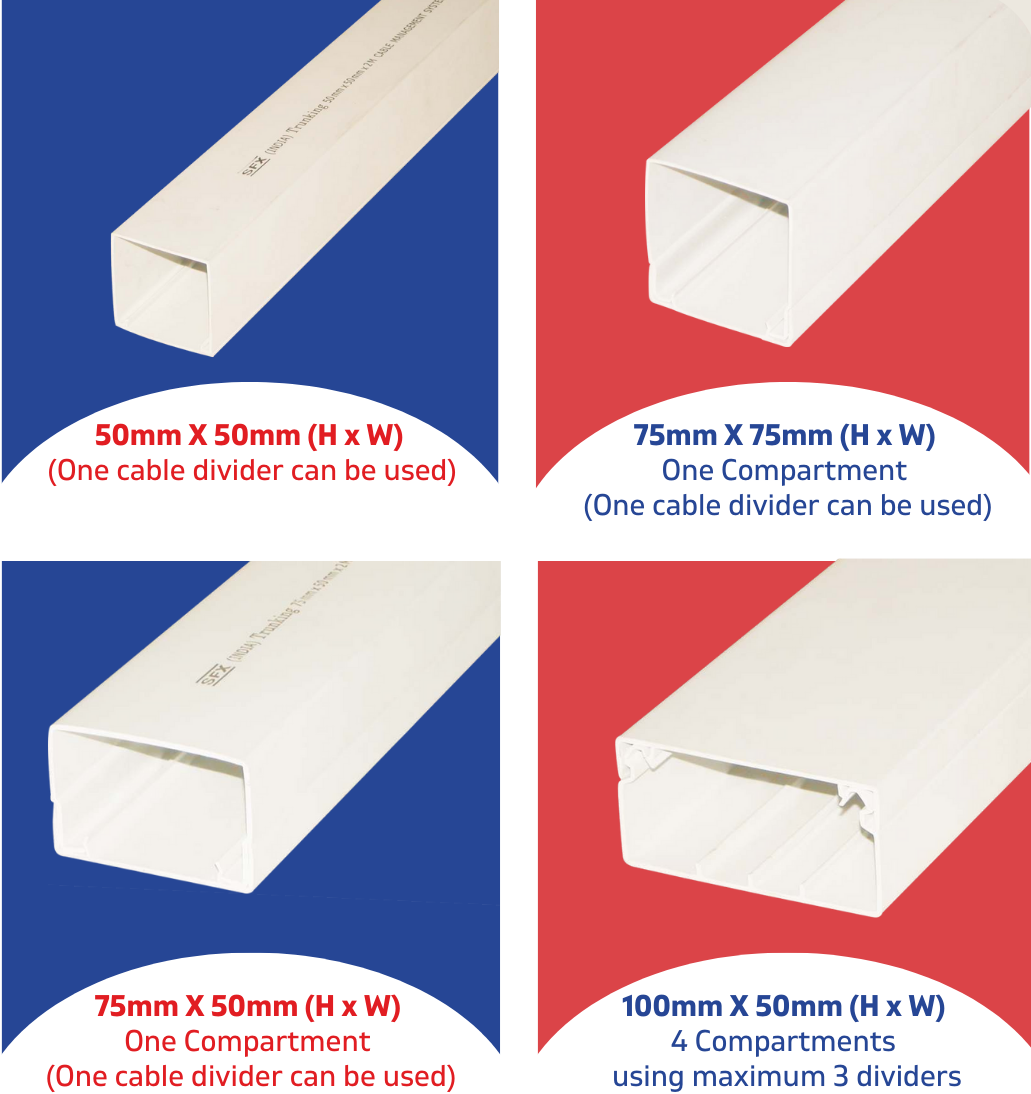

Available in rectangular and square cross-sections, with four size options.

- Standard Length : 2 Meters

- Telecom : High Impact Strength Rigid PVC

- Colour : White

- Thickness : 2.00 to 2.50 mm

Applications

Features

Typical Specifications

Poly Vinyl Chloride characteristics measured at - 23°C

| Particulars | Test Method | Value | Units |

|---|---|---|---|

| Specific Gravity | ASTM D 1784 | 1.4 | |

| Compressive Strength | ASTM D 695 | 540 | Kg / cm² |

| Tensile Strength | ASTM D 638 | 390 | Kg / cm² |

| Flexural Strength | ASTM D 790 | 727 | Kg / cm² |

| Impact | - | 3.6 | cm Kg / cm² |

| Thermal Conductivity | ASTM D 177 | 4.0 | Cal / Sec·cm²·°C / cm ×10 |

| Working Temperature | - | 70 | °C |

| Specific Heat | - | 0.22 | Cal / °C / gm |

| Thermal Expansion | - | 0.063 | mm / m·°C |

| Burning Rate | ASTM D 635 | - | Self Extinguishing |

| Modulus Elasticity in Tension | ASTM D 638 | 19,800 | Kg / cm² |

| Water Absorption | ASTM D 570 | 0.10 | % in 24 hrs |

| Hardness | ASTM D 2240 | 70 | Duro D |

| Dielectric Constant | ASTM D 150 | 1.7 | 60 cps at 30°C |

| Power Factor | ASTM D 150 | 2.52 | 60 cps at 30°C |

| Dielectric Strength | ASTM D 149 | 30 | kV / mm |

Manufacture

Trunking

Appearance

The extruded components have a standard white finish. The moulding components are similar in appearance to the main body in standard white finish.

Workability

Trunk easily cut and drilled with hand tools.

Fire

The material used is non-flame propagating and a Class 1 spread of flame achieved when tested in accordance with the requirements of BS 476 Part-7

Strength

High Impact resistance under normal climatic conditions. Charpy notched impact strength: 25 KJ/m2. Tensile Strength: At yield 34.62N/mm2 At Break 42.00 N/mm2 Density: 1.35 to 1.45

Chemical Resistance

The material used is non-corrosive and not affected by sea water. It has excellent resistance to mineral acids, alkalis and detergents. It offers good resistance to alcohol but liable to attack from solvents such as ketones, aromatic and hydrocarbons.

Durability

PVC material used for Trunk is resistant to vermin and termites. It is stable and will maintain its performance characteristics in accordance with the specifications described above.

Thermal Properties

PVC formulation used in Trunk for cable management can withstand local thermal expansion and construction when installed in accordance with the installation guide. Co-efficient of linear expansion: 5.5 x 10 per °C (6mm x 4000mm with a temperature of 25°C) Operating Temperatures: 5°C to 60°C Vicat Softening point: 81 C Thermal Conductivity: 0.9w/m/°C

-

+

Industries Served

-

+

Product Range

-

+

Customer Trust